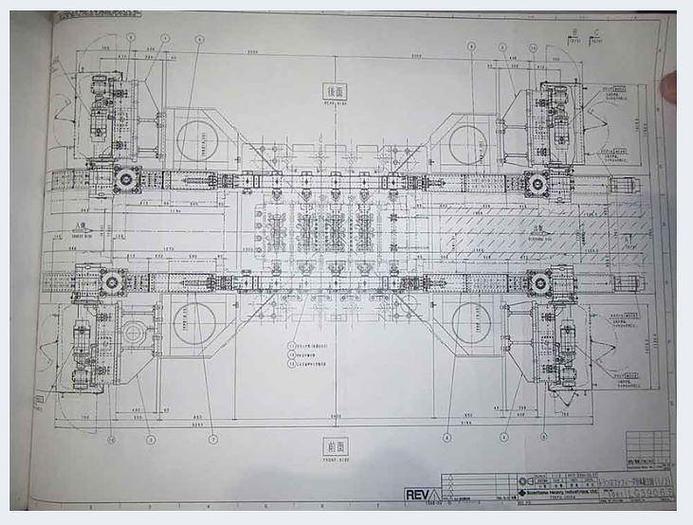

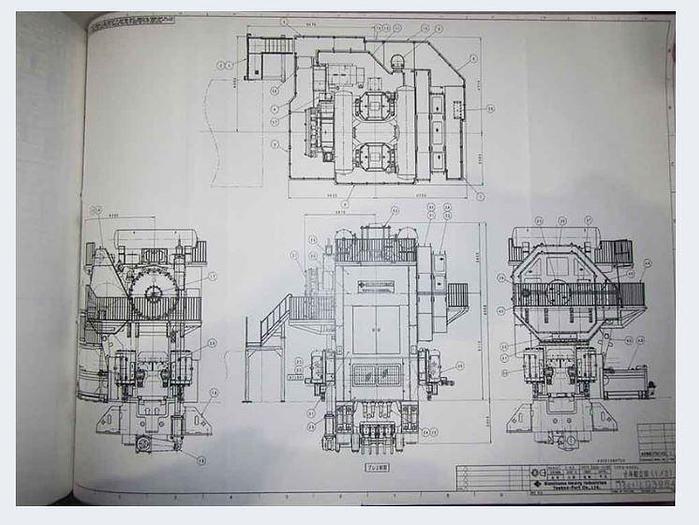

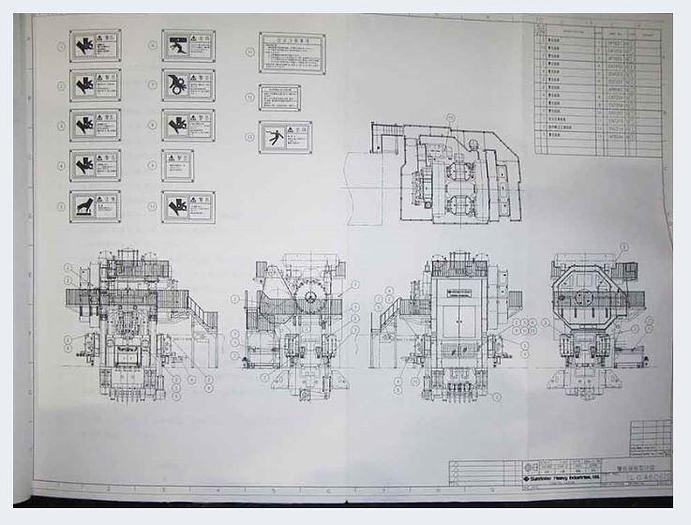

Hot Forging Line Sumitomo TFPX-4500L

Specifications

| Manufacturer | Sumitomo |

| Model | TFPX-4500L |

| Year | 2004 |

| Condition | Used |

| Stock Number | MA2130 |

| Item condition | Good condition |

| Capacity tons | 4500 |

Description

Capacity : 4500 tons,

Stroke : 500 mm,

Shut height : 1300 mm,

Stroke per min : 43,

Bed LR : 2300 mm,

Bed FB : 2100 mm,

Capacity : 45000 kN (on bottom dead center, at 5mm)

Allowed eccentric load : 45000 kN (at 360mm from left-right direction center)

Allowed eccentric load : 20000 kN (at 720mm from center)

Allowed eccentric load : 45000 kN (at 70mm from front-back direction center)

Shut height : 1300 mm,

Stroke : 500 mm,

Stroke per min : 43 (constant),

Maximum number of operations : 20tpm (design Max. 24 tpm),

Maximum operations energy : 66kN-m (at 20 tpm),

Slide hard plate : 2000 mm (LR) (center part max. 2280 mm) x 2100 mm FB),

Bed hard plate : 2300 mm (LR) x 2100 mm (FB),

Frame inside : 2400 mm (LR),

Side opening : 1460 mm (FB),

(Adjustment of shut height)

Adjustment method : eccentric wrist pin swing system,

Push button operation in operation panel,

Adjustment : 10 mm,

Adjustment during automatic operation : max.0.9mm/1shot (at 20tpm),

AC inverter motor : 355kW 1150rpm 400V,

Resistance regeneration system,

Equipped thermo guard.

-Slide knockout -

Type: connection stick operation type, timed knockout,

Capacity: each 5 ton (1st step), each 20 ton (2~4 step),

Stroke : 50 mm,

The number of pins : 4 (1~4 step),

Overload safety equipment: equipped stretch bolt.

-Bottom knockout -

Type: upper limit retention equipped cam type timed knockout,

Capacity : each 30 ton (1~5 step), total 120 ton (Stroke),

Cam : 40, 100 mm (2-step change type),

Cylinder (hydraulic drive) : max. 160 mm (1~3 step),

max. 100 mm (4 and 5 step) Upper limit retention force: each 0.5 ton (1~5step),

The number of pins : 5,

Overload safety equipment : Hydraulic overload protector under operating at 120 ton or more

Frame respiratory volume (shut height expansion amount) : target 3.2 mm, guaranteed 3.3 mm (at center load)

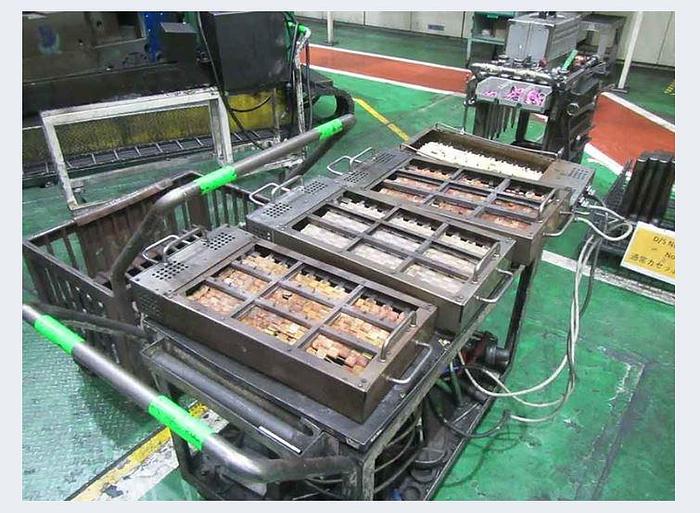

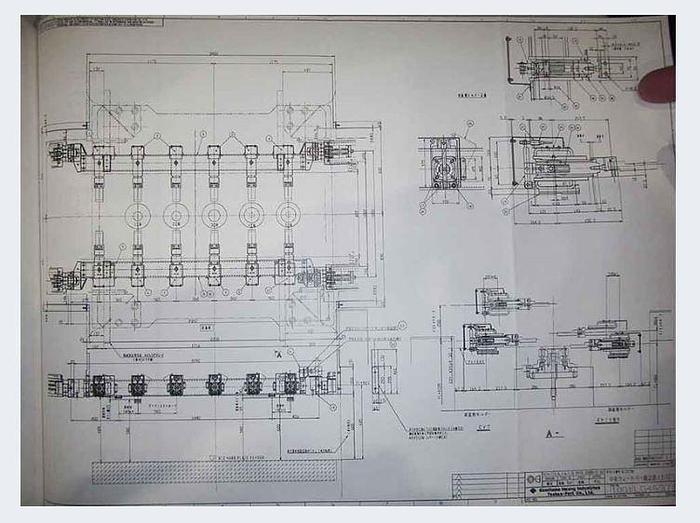

-Transfer feeder -

AC SERVO motor control,

3-dimensional feeder (Separate front and rear drive type),

The number of steps : 5,

Feed stroke : 360mm, 432 mm (2-step change),

Grab stroke : one side 80~130 mm (variable),

Lifting stroke : 60~250 mm (variable),

SPM : 12~20 spm (variable),

Feed direction : from left (brake side) to right (clutch side),

Slight SPM : 5 spm,

Material supply method : continuous, single-handed feed, two-handed feed,

Max. feed weight : weight 30kg, total 90kg (single-handed feed),

Max. feed weight : unit weight 8kg, total 48kg (continuous feed),

Operation method : transfer master type (feeder continuous, press intermittent operation),

AC SERVO motor : Fanuc, total 10 units,

Overload detecting : deviation and motor torque management type,

Grab stroke, Lifting stroke, max. SPM varies depending on the products. Each stroke has an offset function of the following figures.

Feed : 5mm, Grab and Lifting : each 10 mm,

(Accessories)

Overload detecting equipment,

Center feed bar automatic detachable device,

Feeder mistake clamp detection device.

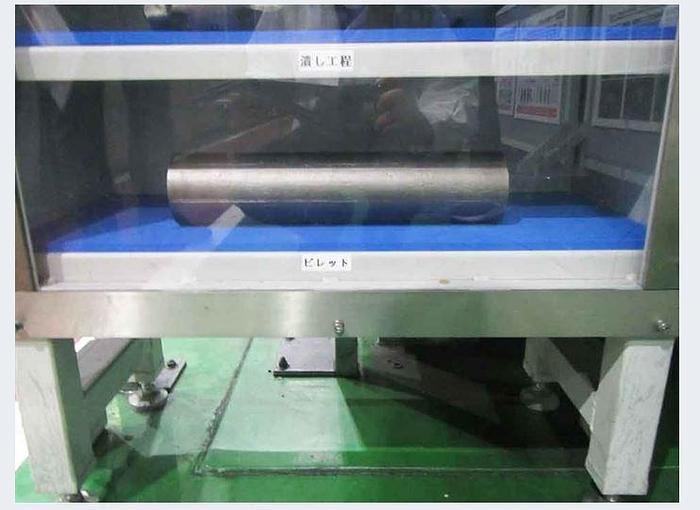

-Charger equipment -

Charge equipment body: by AC SERVO motor drive, Reciprocation type,

Inlet charge conveyor: chain drive, conveyor width (2-step change type),

Conveyor outlet shoot: bird cage type,

The number of conveyors: (1line:for CVT, 1line: gear): shoot position change type Vertical feed change equipment: cylinder cutting out type, billet guide,

Robot hand for Inlet side horizontal feed: chain drive.

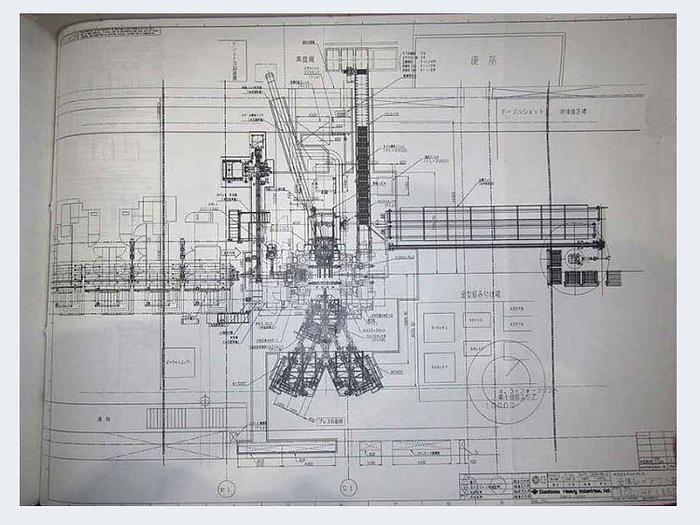

-Die lubricating device-

Moving Nozzle

- Slide interlocking nozzle(equipped with reciprocating motion),

- Stroke : 1050 mm,

- Adjustment of lubrication volume: by timer (operation panel),

- Adjustment of lubrication timing: rotary encoder setting (operation panel) -Pump: 75L/M x 2 units,

Moving Nozzle tip nozzle head: 3units (for crank, for movable, for gear),

Die holder side fixed nozzle,

Air blower.

-Billet size -

Horizontal work

Dia. 40~100 mm, Length 200~490 mm, Max. weight 30 kg,

Vertical work

Dia. 40~90 mm (40~60mm, on two operation), Length 200~490 mm, Length L/D=1.4~2.0, Max. weight 8kg,

(Utilities)

Compressed air : 0.5MPa~0.7 Mpa, consumption 1900 Nm3/H,

Cooling water : 0.2MPa~0.3 MPa, Temp.: 5~35 °C, 12m3/H,

Industrial water: 0.2MPa~0.3MPa, Temp.: 5~35 °C, 6m3/H

(Power supply)

Main motor : 3 phase, 400V±10%, 50Hz,

Auxiliary motor : 3 phase, 200V±10%, 50Hz,

AC SERVO motor : 3 phase, 200V±10%, 50Hz,

Inlet robot: 3 phase, 200V±10%, 50Hz,

Control: 100V, 50Hz.

Weight : approx. 500 tons,

AC Servo transfer system.

Technical manual & foundation drawing available.

Trimming press is included

Manufacturer: Ashi,

Manufacturing year: 2012,

Type: Hydraulic press,

Stroke: 500 mm,

Bolster: 1400 x 1400 mm.

This 4500 tons press is a Mechanical Forging Press with a sophisticated Transfer System designed to produce L4 Crankshafts, CVT Pully shafts, movable, Gears, and Connecting Rods all for automobiles.

It is still set up and available for inspection.